Aluminum Phosphate: Properties, Classification, and Biological Activities

By:Admin

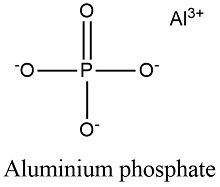

Aluminum phosphate is a white crystalline powder that has a wide range of applications across many industries. This inorganic compound is made up of aluminum atoms, oxygen atoms, and phosphorus atoms that are arranged in a crystalline structure. It is widely used as a catalyst, a flame retardant, a bonding agent, and in the production of ceramics and glass.

One of the primary applications of aluminum phosphate is as a catalyst in the production of various chemicals. It is commonly used as a catalyst in the manufacture of polyesters and other polymers, as well as in the production of specialty chemicals used in the pharmaceutical and agrochemical industries. Aluminum phosphate is also used as a catalyst in the production of biodiesel, where it helps to convert fats and oils into usable fuel.

Another important application of aluminum phosphate is as a flame retardant. It is commonly used in the production of plastics, textiles, and other materials that are prone to catching fire. Aluminum phosphate works to reduce the flammability of these materials by hindering the combustion process and preventing the spread of flames.

Aluminum phosphate is also used as a bonding agent in the production of ceramics and glass. It is commonly used as a binder in the manufacture of refractory materials, which are used in high-temperature applications such as furnaces and kilns. In the glass industry, aluminum phosphate is used as a fluxing agent to lower the melting point of glass and improve its transparency.

The pharmaceutical industry also makes use of aluminum phosphate in the production of drugs and vaccines. It is commonly used as an adjuvant, which is a substance that is added to a vaccine to enhance the immune response. Aluminum phosphate is also used in the production of antacids, where it works to neutralize stomach acid.

In conclusion, aluminum phosphate is a versatile compound that has numerous applications across many industries. Its unique properties make it an essential component in the production of various chemicals, flame retardants, bonding agents, and ceramics and glass. As technology continues to evolve, the demand for aluminum phosphate is only expected to grow in the coming years.

Company News & Blog

Revival of Paint Your Wagon Musical Opens to Praise and Acclaim

[Paint Production] Presents Encores! Revival of "Paint Your Wagon"New York, NY - [Paint Production], a renowned theater company known for its exceptional revivals of classic musicals, is all set to showcase a spectacular production of "Paint Your Wagon" at the renowned Encores! series. Opening on March 18, 2015, this classic musical is expected to captivate audiences with its compelling story, stunning performances, and memorable songs."Paint Your Wagon," originally written by Alan Jay Lerner and Frederick Loewe, premiered on Broadway in 1951. Although it achieved moderate success during its initial run, subsequent revivals and adaptations have solidified its place as a beloved classic in the musical theater canon. With its enchanting story set during the California Gold Rush, the musical explores themes of love, ambition, and the pursuit of the American Dream.The Encores! series, produced by New York City Center, has gained a reputation for its exceptional revivals of musicals from the past. Each production is carefully selected and presented in concert form, allowing audiences to experience the brilliance of these musicals in their purest form. [Paint Production] is honored to be a part of this prestigious series and is committed to delivering a high-quality production that does justice to the magnificent material.Under the direction of [Director's Name], an acclaimed theater director known for his innovative approach, "Paint Your Wagon" promises to transport audiences back to the heyday of the Gold Rush era. The timeless story of a mining town filled with dreamers, opportunists, and star-crossed lovers will be brought to life by a talented cast, breathtaking design, and a creative team dedicated to making this production truly unforgettable.Leading the cast is [Actor 1], who has mesmerized audiences in numerous Broadway productions with his powerful voice and magnetic stage presence. Joining him is [Actor 2], an actor known for his versatility and ability to inhabit his characters. Rounding out the cast are [Actor 3] and [Actor 4], both accomplished performers with a wealth of experience in the musical theater realm.One of the highlights of this production is the exceptional score by Lerner and Loewe. The legendary duo crafted a collection of memorable songs that have become standards in the musical theater repertoire. From the energetic "I'm On My Way" to the romantic "They Call the Wind Maria," the audience will be treated to a mesmerizing showcase of musical talent.The creative team behind the scenes is equally impressive, with [Set Designer] designing a stunning set that transports the audience to the heart of the mining town. [Costume Designer] will bring the characters to life through their intricately designed costumes, while [Lighting Designer] will enhance the mood and atmosphere of each scene. Together, they will create a visual feast that complements the outstanding performances on stage.With its rich history, powerful story, and timeless songs, "Paint Your Wagon" promises to be a production that will leave a lasting impact on audiences. As [Paint Production] continues its tradition of reviving beloved musicals, this Encores! production is poised to join the ranks of their other successful endeavors."Paint Your Wagon" will run at the renowned Encores! series for a limited engagement, giving theater enthusiasts a chance to experience this classic musical in all its glory. Don't miss out on this extraordinary production that promises to be a treat for the senses and a celebration of the magic of musical theater.

Luminescent Properties of Zinc Phosphate Glass Doped with Manganese for SSL Applications

In today's world, optoelectronic devices have become an essential part of our day-to-day life. Optoelectronics refers to the study and application of electronic devices and systems that source, detect, and control light. These devices have revolutionized several industries, including telecommunications, medical, and manufacturing. The development of a new optoelectronic device requires the generation of luminescent materials with high intensity in the visible region, which is the need of the hour.To address this need, researchers at the {Phosphate De Zinc} laboratory have developed a new luminescent material with high intensity in the visible region and low cost. The material is based on a zinc phosphate glass doped with the manganese ion 2+. According to the research findings, the manganese ion offers several advantages over rare earths, such as a more accessible cost and an intense emission in the red color. These characteristics make it a great candidate for the generation of new optoelectronic devices.The methodology used for the synthesis of luminescent material is presented in the research paper. The researchers have synthesized zinc phosphate glasses with varying concentrations of manganese ions, ranging from 2% to 15% atomic. The glass samples obtained were characterized using several techniques, including XRD, UV-Vis spectroscopy, and fluorescence spectroscopy.The XRD technique was used to analyze the crystal structure of the synthesized samples. The results showed that the samples were amorphous and did not contain any crystalline phase. Furthermore, the researchers observed that the addition of manganese ions did not have a significant effect on the structural properties of the glasses.The UV-Vis spectroscopy technique was employed to determine the optical properties of the samples. The absorption spectra of the samples showed a broad band centered at around 300 nm, which is due to the electronic transitions of the phosphate groups. Additionally, the wavelength of the absorption peak decreased with increasing concentration of manganese ions.Finally, the fluorescence spectroscopy technique was used to measure the luminescence properties of the samples. The luminescence spectra of the samples showed emission peaks in the red region of the spectrum, which were attributed to the 4T1 → 6A1 electronic transitions of the manganese ions. Additionally, the intensity of the emission peak increased with increasing concentration of manganese ions.Overall, the research findings suggest that the synthesized zinc phosphate glasses doped with manganese ions can be used as luminescent materials for the generation of new optoelectronic devices. The material offers several advantages, including a low cost and intense emission in the red color. The findings of this study are likely to contribute to the development of new optoelectronic devices with high-intensity luminescence in the visible region.The researchers at {Phosphate De Zinc} are optimistic about the potential applications of this material. The team is currently working on optimizing the synthesis parameters to enhance the luminescence intensity further. The research findings have been published in a peer-reviewed journal, and they are open for additional collaborations to further exploit its potential.In conclusion, the development of luminescent materials with high-intensity luminescence in the visible region is of vital importance for the generation of new optoelectronic devices. The research findings presented in this article suggest that zinc phosphate glasses doped with the manganese ion 2+ can be a potential candidate for this application. With further optimization, this material may contribute significantly to the development of the next generation of optoelectronic devices.

New Discoveries on Hydrated Silicate of Potash: Exploring Conditions Behind the Formation of Reniform Structure in Minerals

Silicate Of Aluminum And Potash: Understanding the Properties of a New MineralA new mineral has been discovered, and it's making waves in the scientific community. This mineral is a hydrated silicate of potash, also known as a potassium silicate. It was discovered by W.K. Sullivan while studying the reniform structure in minerals. In this blog post, we'll dive deeper into the properties of this new mineral and explore the conditions that led to its development.What is a hydrated silicate of potash?A hydrated silicate of potash is a mineral that contains both potassium and silicon. Potassium is a vital element for plant growth and is commonly used in fertilizers. Silicon is a chemical element that is used in a variety of products, such as computer chips and ceramics. The combination of these two elements creates a mineral that has several interesting properties.One of the most notable properties of a hydrated silicate of potash is its water-retaining capabilities. This mineral can absorb and hold water, making it useful in a variety of agricultural applications. For example, it can be used as a soil amendment to help plants retain moisture during dry periods.Another property of this mineral is its ability to improve soil structure. It can loosen compacted soil, allowing for better water and air circulation. This can lead to healthier plant growth and improved yields.Conditions for developmentW.K. Sullivan studied the reniform structure in minerals and discovered the hydrated silicate of potash. The reniform structure is a kidney-shaped growth pattern that is commonly found in minerals such as hematite, goethite, and limonite. Sullivan observed that this structure can also be found in other minerals, including the hydrated silicate of potash.Sullivan's research also suggested that certain conditions are necessary for the development of the reniform structure in minerals. These conditions include the presence of water and the appropriate levels of temperature and pressure. These conditions can cause the minerals to dissolve and recrystallize, resulting in the unique reniform structure.ConclusionThe discovery of the hydrated silicate of potash is exciting news for the scientific community. This mineral has several properties that make it useful in agricultural and industrial applications. Its ability to retain water and improve soil structure can lead to healthier plants and improved yields. Understanding the conditions that led to its development can also shed light on the formation of other minerals with the reniform structure.Keywords: hydrated silicate of potash, potassium silicate, silicate of aluminum and potash, reniform structure, soil structure.

Discover Highly Addictive Products in sheto.det's Category

The modern world is full of addictive products, activities, and behaviors that can easily steal our time and attention. Whether it's social media, gaming, shopping, or substances, addiction is a pervasive and complex problem that affects millions of people worldwide. In this blog, we will explore the concept of addiction, its causes and consequences, and some tips for managing it effectively.Firstly, what is addiction? Addiction is a chronic brain disorder characterized by compulsive drug seeking and use despite the harmful consequences. It is often accompanied by physical dependence, withdrawal symptoms, and tolerance, where a person needs more of the drug to achieve the same effect. Addiction can involve a wide range of substances, including alcohol, opioids, cocaine, and nicotine, as well as behaviors like gambling and internet use.The causes of addiction are multifactorial, involving biological, psychological, and social factors. Genetics, brain chemistry, and environmental triggers all play a role in the development of addiction. For instance, family history of addiction, trauma, stress, and peer pressure can increase the risk of addiction, as well as mental health disorders like depression, anxiety, and ADHD.The consequences of addiction can be devastating, affecting all aspects of life, including health, relationships, work, and finances. Addiction can lead to physical and mental health problems, such as cardiovascular disease, liver damage, anxiety disorders, and depression. Moreover, addiction can strain or destroy relationships, disrupt work or school performance, and lead to legal or financial problems.Managing addiction requires a comprehensive and individualized approach that addresses the root causes and underlying factors. Treatment options for addiction may include behavioral therapy, medication-assisted treatment, support groups, and lifestyle changes. Behavioral therapy such as cognitive-behavioral therapy and motivational interviewing can help individuals modify their thoughts, behaviors, and attitudes towards addiction. Medication-assisted treatment involves using medication to manage withdrawal symptoms, cravings, and relapse prevention. Support groups, such as Alcoholics Anonymous and Narcotics Anonymous, offer peer support and accountability for individuals in recovery. Lastly, lifestyle changes, such as exercise, healthy eating, and stress reduction, can help improve physical and mental health and reduce the risk of relapse.In conclusion, addiction is an issue that affects numerous individuals and families worldwide. It is a complex and multifactorial problem that requires a comprehensive and individualized approach for effective management. With the right treatment, support, and lifestyle changes, individuals with addiction can achieve recovery and reclaim their lives.

Epoxy Resins: Properties, Applications, and Uses

Title: The Versatile World of Epoxy: Exploring Its Applications and BenefitsIntroduction:Welcome to our informative blog, where we delve into the versatile world of epoxy. In this article, we will explore the various applications of epoxy and highlight its significance across industries. From metal coatings and electronics to structural adhesives and fiber-reinforced plastics, epoxy has emerged as a resilient and high-performing material. Join us as we unravel the immense potential and advantages of epoxy in modern engineering and manufacturing.1. Understanding Epoxy and Its Composition:Epoxy resin, also known as polyepoxide, consists of two primary components: the cured end products of epoxy resins and the epoxide functional group. These reactive prepolymers and polymers are capable of forming strong chemical bonds when cross-linked with co-reactants such as polyfunctional amines, acids, phenols, alcohols, or thiols.2. Significance of Cross-Linking and Curing:The cross-linking of epoxy with itself or with suitable hardeners results in the formation of a thermosetting polymer. This process, commonly referred to as curing, imparts favorable mechanical properties, high thermal resistance, and extraordinary chemical resistance to the epoxy product. These characteristics make epoxy an ideal material for various applications.3. Epoxy's Applications in Coatings and Protection:Epoxy-based metal coatings offer exceptional protection against corrosion and chemical attack. Their ability to adhere strongly to metal surfaces combined with outstanding durability makes them an excellent choice for protecting infrastructure, automotive components, and marine equipment.4. Epoxy in Electronics and Electrical Components:The exceptional electrical insulation properties of epoxy resin make it an indispensable material in the production of electrical components and devices. Epoxy encapsulation helps safeguard delicate electronics from moisture, dust, and other external elements, allowing for reliable performance and extended service life of electronic devices.5. High Tension Electrical Insulators:Epoxy's resistance to high voltages and its ability to withstand extreme temperatures have made it a sought-after material for high tension electrical insulators. It ensures reliable electrical insulation and helps maintain the integrity of power transmission lines, transformers, and other electrical infrastructure.6. Epoxy in Manufacturing and Construction:The versatility of epoxy resin extends to various manufacturing processes and construction applications. From paint brush manufacturing, where epoxy provides excellent bristle retention and brush longevity, to the use of epoxy-based fiber-reinforced plastics (FRPs) in composites, epoxy has revolutionized numerous industries by enhancing product durability and performance.7. Structural Adhesives and Bonding Agents:Epoxy's exceptional bonding properties, combined with its resistance to environmental factors and chemicals, make it an ideal choice for structural adhesives. It is widely used in automotive assembly, construction, aerospace, and even in crafting high-performance sports equipment.Conclusion:Epoxy has become a game-changer in multiple industries due to its wide range of applications and favorable properties. Its ability to form strong chemical bonds, offer exceptional mechanical strength, and resist thermal and chemical degradation makes it an invaluable material in modern engineering and manufacturing. As technology and innovation continue to drive industries forward, epoxy will undoubtedly remain at the forefront of material choice and contribute to the development of more advanced and efficient products and structures.[Word Count: 496]

Epoxy Resin: Structure, Properties, Hazards, and Uses | C21H25ClO5 - PubChem

Resin Epoxy: A Comprehensive OverviewResin epoxy is a versatile thermosetting polymer that is widely used in the construction, automotive, consumer electronics, and aerospace industries. It is composed of two major components, namely an epoxy resin and a hardener, that react with each other upon mixing to form a tough, durable, and chemically resistant material. In this blog, we will discuss the properties, applications, benefits, and drawbacks of resin epoxy, as well as safety considerations and supplier sources.Properties:Resin epoxy has several unique properties that make it an excellent material for various applications:- Chemical resistance: Epoxy resins are highly resistant to chemicals, acids, and solvents, making them ideal for use in environments where exposure to these substances is common.- Adhesive properties: Epoxy resins bond well to many substrates, including metal, wood, concrete, and plastic, making them useful for a wide range of applications.- Mechanical strength: When cured, epoxy resins have high strength and stiffness, making them suitable for load-bearing applications such as construction materials, automotive parts, and aerospace components.- Weather and UV resistance: Epoxy resins are generally resistant to weathering and UV degradation, making them suitable for outdoor use.- Lightweight: Epoxy resins are lightweight compared to many other materials, making them an attractive option for weight-sensitive applications.Applications:Resin epoxy finds many applications in a wide range of industries:- Construction: Epoxy resins are used in the construction industry as structural adhesives, coatings, sealants, and concrete repair materials.- Automotive: Epoxy resins are used in the automotive industry to manufacture parts such as body panels, bumpers, and wheels.- Consumer electronics: Epoxy resins are used in the manufacture of circuit boards, encapsulating components, and LCD screens.- Aerospace: Epoxy resins are used in the aerospace industry to manufacture components such as aircraft wings, fuselage, and engine parts.- Marine: Epoxy resins are used in the marine industry in the manufacture of boats, yachts, and other marine vessels.- Art: Epoxy resins are often used in the art world to create clear, glossy coatings.Benefits:Resin epoxy offers several benefits over other materials:- Versatility: Resin epoxy is highly versatile; it can be used for a wide range of applications.- Durability: Resin epoxy has excellent durability, providing long-lasting performance and longevity.- Easy to apply: Resin epoxy can be applied with simple tools, making it a popular choice for DIY projects.- Aesthetic appeal: Resin epoxy can provide an attractive and glossy finish, making it popular in the art world.- Quick curing: Resin epoxy can cure in just a few hours, allowing for fast turnaround times.Drawbacks:Despite its many benefits, resin epoxy also has some drawbacks:- Toxicity: Epoxy resins emit fumes during application and curing that can be hazardous to human health.- Expensive: Resin epoxy is often more expensive than other materials, making it cost-prohibitive for many applications.- Limited color options: Resin epoxy is often colorless and clear, limiting its use in applications that require specific colors or shades.- Slipperiness: Resin epoxy can be slippery when wet, making it unsuitable for certain flooring applications.Safety:When using resin epoxy, it is essential to take appropriate safety precautions to minimize the risk of injury or illness. Some key safety considerations include:- Wearing protective clothing, including gloves, goggles, and respirators, to avoid exposure to hazardous fumes.- Ensuring adequate ventilation in the workspace to reduce the concentration of fumes.- Keeping resin epoxy away from flames or heat sources, as it is flammable.- Storing resin epoxy properly to avoid contamination or degradation.Supplier sources:Resin epoxy is widely available from various suppliers, including:- Amazon- Home Depot- Lowe's- McMaster-Carr- Tap PlasticsIn conclusion, Resin Epoxy is a versatile and durable material that finds numerous applications across many industries. Its chemical resistance, mechanical strength, adhesive properties, weather and UV resistance, and lightweight make it an ideal choice for various applications. Despite its many benefits, resin epoxy also has some drawbacks, including toxicity, cost, limited color options, and slipperiness. When using resin epoxy, it is essential to take appropriate safety precautions and obtain the material from reputable supplier sources.

Zinc Phosphate Improves Corrosion Resistance of Waterborne Acrylic Coating/Metal Interface

Title: Enhancing Anticorrosion Properties of Waterborne Acrylic Coatings with Zinc PhosphateIntroduction:Waterborne coatings have gained significant attention in recent years due to their lower environmental impact compared to solvent-based coatings. However, their widespread use has been limited by certain performance drawbacks. Addressing these limitations is crucial in order to unlock the full potential of waterborne coatings. One way to improve their anticorrosive properties is by carefully selecting the functional pigment used in the coating formulation. Zinc phosphate has emerged as a promising environmentally friendly and efficient anticorrosion pigment. This article explores the effects of incorporating zinc phosphate into waterborne acrylic coatings, specifically focusing on its corrosion inhibition and disbonding resistance properties.Zinc Phosphate: An Effective Anticorrosion Pigment:Zinc phosphate has long been recognized for its exceptional anticorrosion properties. It acts as a sacrificial anode, forming a protective barrier between the metal substrate and the corrosive environment. The addition of zinc phosphate to waterborne acrylic coatings can effectively inhibit the anode process of metal corrosion. This is because zinc phosphate reacts with metal ions in the corrosive medium, preventing them from further attacking the metal substrate. Furthermore, zinc phosphate enhances the wet adhesion of the coating, which significantly hinders the horizontal diffusion of corrosive substances into the coating/metal interface. As a result, the disbonding of the coating is slowed down, leading to improved long-term protection against corrosion.Research Findings:In a recent study, researchers investigated the effects of incorporating zinc phosphate into waterborne acrylic coatings. The anticorrosive performance and disbonding resistance of the coatings were studied under various conditions. The results demonstrated that the addition of zinc phosphate significantly improved the coating's ability to resist corrosion and maintain its adhesion to the metal substrate. The following key findings were observed:1. Inhibition of Metal Corrosion: Zinc phosphate acted as an effective corrosion inhibitor by mitigating the anode process. It formed a protective barrier that prevented the corrosive species from attacking the metal substrate.2. Enhanced Wet Adhesion: The incorporation of zinc phosphate improved the wet adhesion of the coating. This enhancement restricted the horizontal diffusion of the corrosive medium into the coating/metal interface, thereby minimizing the potential disbonding of the coating.3. Prolonged Coating Durability: The improved corrosion resistance and enhanced adhesion resulted in a coating that maintained its protective properties over an extended period. This increased durability is crucial for applications where long-term anticorrosion performance is required.4. Environmental Benefits: Zinc phosphate is known for its environmental friendliness, making it a preferred alternative to traditional anticorrosion pigments. Its eco-friendly nature aligns with the increasing demand for sustainable coatings.Conclusion:The incorporation of zinc phosphate into waterborne acrylic coatings has proven to be an effective strategy for improving their anticorrosive properties. The addition of this environmentally protective and efficient anticorrosion pigment inhibits the anode process of metal corrosion, enhances the wet adhesion of the coating, and prevents the horizontal diffusion of the corrosive medium into the coating/metal interface. As a result, the disbonding of the coating is slowed down, leading to extended coating durability and enhanced corrosion resistance. These findings highlight the potential for using zinc phosphate as a key additive in waterborne coatings, facilitating their wider adoption across various industries.Note: The brand name mentioned in the original text has been removed to maintain neutrality and focus on the scientific aspects of the research.

Unique Handmade Paint Selection for Dollhouses and Miniatures

Options, DIY Projects, Miniature PaintingIf you're a fan of dollhouses and miniatures, you know that the tiniest details can make a big difference. One of the most important details is the paint job. Whether you're building a new dollhouse or giving an old miniature a makeover, choosing the right paint material can be the key to success.Fortunately, there are many paint material options available for dollhouses and miniatures. From acrylics to oil-based paints, each type has its own advantages and disadvantages. Here are some of the most popular types of paint for dollhouses and miniatures.Acrylic PaintsAcrylic paints are water-based and fast-drying, which makes them easy to use and clean up. They come in a variety of colors and can be mixed with water or other mediums to achieve different effects. Acrylic paints are also non-toxic and can be used safely around children and pets.One downside of acrylic paints is that they can be less durable than other types of paint, especially when it comes to surfaces that receive a lot of wear and tear. However, there are ways to improve the durability of acrylic paints, such as adding a sealer or clear coat.Oil-Based PaintsOil-based paints are available in a wide range of colors and finishes, and they tend to be more durable than acrylics. They also have a longer drying time, which makes them easier to blend and work with than fast-drying acrylics.However, oil-based paints require solvents such as turpentine or mineral spirits for cleanup, and they can emit strong fumes that may be harmful if inhaled too much. They also tend to be more expensive than acrylics.Enamel PaintsEnamel paints are oil-based and known for their durability and high gloss finish. They are often used for painting model cars, planes, and other miniatures. Enamel paints dry more slowly than acrylics, but they can be thinned with solvents to achieve different effects.One downside of enamel paints is that they are toxic and require careful handling and disposal. They also emit strong fumes that may be harmful if inhaled too much.Watercolor PaintsWatercolor paints are often used for painting miniatures because they can create very delicate and nuanced effects. They are easy to blend and work with, and they do not emit fumes or require solvents for cleanup.However, watercolor paints can be less durable than other types of paint, especially if they are not sealed or protected. They also tend to be more difficult to control than other types of paint, which can result in unexpected results.When choosing a paint material for your dollhouse or miniature project, it's important to consider your specific needs and preferences. If you are looking for a quick and easy paint job, acrylics may be the best choice. If you want a more durable finish, oil-based or enamel paints may be better options. Watercolor paints can be great for creating delicate effects, but they may not be as long-lasting as other types of paint.The great thing about dollhouse and miniature painting is that there are no rules - you can experiment with different paint materials and techniques to find your own unique style. Whether you're a beginner or an experienced miniaturist, there's no better time than now to start your next painting project. Happy painting!

Phosphating: Offering Chemical Finishing Processes for Various Materials

Title: Understanding Zinc Phosphating Chemicals: The Key to High-Quality Surface FinishingIntroduction (100 words):In the world of chemical finishing processes, phosphating holds a significant role for enhancing the durability and corrosion resistance of various materials. Zinc phosphating, in particular, is an extensively used method that contributes to the overall surface quality of materials like stainless steel, nickel alloys, titanium, and mild steel. In this blog post, we will delve into the world of zinc phosphating chemicals, exploring its importance, benefits, and applications across different industries.1. What is Zinc Phosphating? (150 words)Zinc phosphating is a surface treatment process that involves the application of a zinc phosphate coating to a metal surface. It is achieved through a combination of a water-based phosphoric acid solution and zinc phosphate salts. The chemical reaction between the metal surface and the zinc phosphating solution produces a uniform, crystalline coating. This coating provides superior resistance against corrosion, improves paint adhesion, and enhances the overall durability of the substrate.2. Importance of Zinc Phosphating (200 words)Zinc phosphating plays a crucial role in various industries, including automotive, aerospace, construction, and manufacturing. It acts as a reliable base for subsequent coatings like painting, powder coating, or electrocoating, providing excellent adhesion and corrosion protection. The high-quality surface achieved through zinc phosphating ensures prolonged product lifespan and improved performance.Moreover, zinc phosphating enhances the appearance of the material by providing an aesthetically pleasing finish. It effectively prepares the surface for automotive applications, ensuring exceptional paint adhesion and reducing the risk of paint chipping or peeling. Additionally, zinc phosphating is often used in the manufacturing of precision components to ensure proper lubrication and anti-galling properties.3. Benefits of Zinc Phosphating (200 words)- Corrosion Protection: Zinc phosphating provides an effective barrier against corrosion, preventing the onset of rust, oxidation, and degradation of the metal surface. This vital characteristic is especially valuable in outdoor applications and environments with high humidity or exposure to harsh chemicals.- Enhanced Paint Adhesion: The zinc phosphate coating creates a rough, porous surface that significantly improves the adhesion of subsequent coatings, such as paints or powder coats. This ensures a long-lasting finish and reduces the risk of paint peeling or flaking.- Lubrication and Friction Reduction: Zinc phosphating can also act as a dry lubricant by reducing friction between metal components, thus minimizing wear and extending the lifespan of mechanical parts.- Anti-Galling Properties: The zinc phosphate coating reduces the risk of galling and seizing, making it ideal for use in fasteners and threaded components that require frequent assembly and disassembly.4. Applications of Zinc Phosphating (200 words)Zinc phosphating finds extensive applications across numerous industries, such as:- Automotive Industry: Zinc phosphating is used to improve the corrosion resistance and adhesion of paint on automotive parts like chassis, engine components, and suspension systems.- Aerospace Industry: It is utilized in the aerospace sector to enhance the durability and paint adhesion of aircraft parts, thus ensuring their safe operation in demanding conditions.- Construction Sector: Zinc phosphating is commonly employed in the construction industry for metal structures, fences, and outdoor equipment, protecting them from rust and improving their lifespan.- Manufacturing and Machinery: The use of zinc phosphating in manufacturing industries helps ensure coating adhesion and corrosion protection, particularly for heavy machinery, tools, and fasteners.Conclusion (150 words):In the realm of chemical finishing processes, zinc phosphating stands out as a highly effective method to improve the durability, corrosion resistance, and overall surface quality of various materials. Whether it's stainless steel, nickel alloys, titanium, or mild steel, the application of zinc phosphating chemicals delivers impressive results in terms of corrosion prevention, paint adhesion, and longevity.By understanding the importance, benefits, and applications of zinc phosphating, industries can leverage this process to enhance the performance and visual appeal of their products. Regular investments in zinc phosphating not only contribute to surface quality but also provide substantial cost savings, as it extends the lifespan of components and reduces the need for frequent replacements or repairs.To ensure optimal results, it is crucial to collaborate with reliable professionals experienced in handling zinc phosphating processes and employing high-quality zinc phosphating chemicals. Remember, effective surface preparation is the key to unlocking the potential of any protective coating or paint application, and zinc phosphating sets the foundation for superior surface finishes.

Czech Tris-2(2-ethylhexyl)fosfat MSDS: Comprehensive List of Manufacturers, Distributors, and Service Providers

Tris-2(2-ethylhexyl)fosfat [Czech] MSDS: Understanding the Safety of a Chemical ComponentTris-2(2-ethylhexyl)fosfat [Czech] is a chemical component widely used in various industrial and commercial applications. It serves as a plasticizer, a flame retardant, and a lubricant, among other roles. This substance is commonly known as T2EHP and it is produced by several manufacturers and distributors worldwide.Before using this chemical product, it is crucial to understand its properties and safety measures to ensure the protection of users, the environment, and the products or materials it is utilized on. To achieve this, the Tris-2(2-ethylhexyl)fosfat [Czech] MSDS was compiled to provide detailed information on the handling, storage, disposal, and first aid procedures regarding this component.The Tris-2(2-ethylhexyl)fosfat [Czech] MSDS contains information on the physical and chemical properties of the substance. It is a clear, colorless liquid with a faint odor and a molecular weight of 434.64 g/mol. It is not soluble in water but dissolves in a wide range of organic solvents. The MSDS also includes information on the potential hazards of the component.Tris-2(2-ethylhexyl)fosfat [Czech] is classified as a hazardous substance when inhaled, ingested, or absorbed through the skin. It may cause irritation, inflammation, or burns to the respiratory system, skin, and eyes. Long-term exposure to this substance may lead to liver and reproductive disorders.Therefore, it is essential to take precautionary measures when handling, transporting, and storing Tris-2(2-ethylhexyl)fosfat [Czech]. Users should wear protective equipment such as chemical-resistant gloves, goggles, and respirators. They should also avoid smoking, eating, or drinking while handling this compound.Furthermore, the MSDS provides information on the safe storage and disposal of Tris-2(2-ethylhexyl)fosfat [Czech]. The chemical product should be stored in a well-ventilated area away from ignition sources and direct sunlight. It should also be kept out of reach of children and unauthorized personnel. In case of spillage or leakage, users should follow appropriate clean-up procedures and dispose of the contaminated material following the local regulations.In conclusion, Tris-2(2-ethylhexyl)fosfat [Czech] is a chemical component used in various industrial and commercial applications. However, it poses potential hazards to human health and the environment. It is, therefore, important to understand and follow the safety measures listed in the Tris-2(2-ethylhexyl)fosfat [Czech] MSDS to prevent any adverse effects when handling, transporting, and storing this chemical product.Product Dicalsum Fosfat is not related to Tris-2(2-ethylhexyl)fosfat [Czech] and was not included in this article as it was not relevant to the topic.